Critical Mass Wins 2026 Independent Press Award

We are proud to share that Critical Mass: The One Thing You Need to Know About Green Cars has been named a 2026 Independent Press Award Winner.

In an era where climate change dominates global discussion, Critical Mass sees Felix our CEO, Nick Molden and Felix Leach unpack the complexity of vehicle emissions with clarity and rigour. Building on insights from Felix’s previous work, Racing Toward Zero, the book tackles the often-confusing landscape of automotive pollution by asking a deceptively simple question: what single piece of information best captures the true environmental impact of cars?

We are proud to share that Critical Mass: The One Thing You Need to Know About Green Cars has been named a 2026 Independent Press Award Winner.

In an era where climate change dominates global discussion, Critical Mass sees Felix our CEO, Nick Molden and Felix Leach unpack the complexity of vehicle emissions with clarity and rigour. Building on insights from Felix’s previous work, Racing Toward Zero, the book tackles the often-confusing landscape of automotive pollution by asking a deceptively simple question: what single piece of information best captures the true environmental impact of cars?

Written for a digital age awash with information but eluded of meaningful understanding, Critical Mass challenges oversimplified narratives around road transport and sustainability. Leach and Molden advocate for a more sophisticated, yet accessible perspective about emissions, examining the real-world impacts of different vehicle powertrains and moving beyond CO₂ alone to consider wider environmental and societal effects.

The Independent Press Award recognises excellence in independent publishing and honours books that demonstrate strong editorial quality, originality, and relevance. Being selected as a 2026 winner reflects the growing importance of transparent, factual analysis in climate and mobility discussions.

At Emissions Analytics, our work has always focused on delivering robust, independent data to inform policymakers, industry leaders and the public. This award reinforces the value of applying the same rigorous approach beyond research and into public-facing dialogue.

We would like to thank the Independent Press Award judges, Gabrielle Olczak from IPA, Sherry Nigam and SAE International for your support as publishers, our readers and everyone who has engaged with the book since its publication.

Find the full award listing here:

https://www.independentpressaward.com/2026-winners/9781468608212

Nick Molden recognised as Fellow of the Royal Society of Chemistry

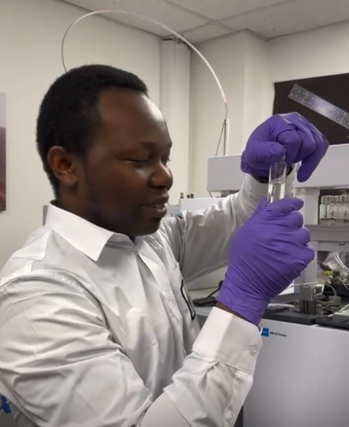

We are delighted to share that Emissions Analytics and Oxford Indices, founder and CEO, Nick Molden, has been admitted as a Fellow of the Royal Society of Chemistry (FRSC).

Fellowship is awarded to those who have made an outstanding contribution to the chemical sciences. Nick’s admission recognises his pioneering work to expand the boundaries of real-world environmental testing, particularly in relation to vehicle emissions, tyre wear particles and indoor air quality.

Nick Molden FRSC

We are delighted to share that Emissions Analytics and Oxford Indices, founder and CEO, Nick Molden, has been admitted as a Fellow of the Royal Society of Chemistry (FRSC).

Fellowship is awarded to those who have made an outstanding contribution to the chemical sciences. Nick’s admission recognises his pioneering work to expand the boundaries of real-world environmental testing, particularly in relation to vehicle emissions, tyre wear particles and indoor air quality.

“This Fellowship reflects a commitment I made five years ago to build world-leading capability in analytical chemistry that could uncover the full environmental impact of vehicles. From tyres to fuels to air quality, we’ve developed original methods, filed patents and conducted over a thousand advanced tests to turn complex chemistry into meaningful action.” - Nick Molden

Over the last five years, Nick has spearheaded Emissions Analytics’ strategic expansion into analytical chemistry, with a focus on quantifying and communicating the real-world environmental impacts of vehicles and materials. This work includes developing novel methodologies for the chemical analysis of tyres, fuels, exhaust and indoor air, using advanced techniques such as two-dimensional gas chromatography and time-of-flight mass spectrometry (GCxGC-TOF-MS).

Through this work, Nick is an author on many peer-reviewed papers, led the development of standardised test protocols and built a dedicated team of researchers and analysts. He continues to drive the company’s testing capability into new areas, including soil and water.

“By choice, I run a specialist team at Emissions Analytics and Oxford Indices. These specialists are picked not just for their skills but also their understanding of our mission to reveal real-world vehicle pollution.” - Nick Molden

In addition to his scientific work, Nick plays a leading role in public engagement. He is co-author of Critical Mass, a book written with Professor Felix Leach (University of Oxford), which presents a compelling case for using vehicle weight as a proxy for environmental impact. He has also given evidence to legislative bodies, including the UK Parliament and the European Parliament, while he also serves as an expert witness in major international legal cases.

Critical Mass

Professor Felix Leach & Nick Molden FRSC

“I’m honoured to be admitted as a Fellow of the Royal Society of Chemistry. This recognition reflects not only my personal journey into analytical science but the extraordinary efforts of the team at Emissions Analytics. By applying advanced chemical analysis to real-world problems, from tyre emissions to indoor air quality, we’re helping to reveal the hidden impacts of everyday products and push for constructive, evidence-based solutions.” - Nick Molden.

Nick holds an Honorary Senior Research Fellowship at Imperial College London and actively collaborates with more than 20 universities around the world. He is the founder and programme lead of the Tyre Emissions & Sustainability conference series in Europe and the US, which brings together global experts to share insights and solutions in this critical and emerging field.

From exposing diesel vehicle emissions during the ‘Dieselgate’ scandal to driving new standards for tyre testing and consumer diagnostics, Nick continues to champion independent science and constructive dialogue. His FRSC recognition reflects not only his personal commitment to evidence-based environmental improvement but also the growing importance of chemistry in addressing today’s most urgent air quality and sustainability challenges.

Why you should be interested in tyres

A surprisingly compelling subject

Dinner table, or social media, conversation may centre on arguments over which football team deserves to win the league, or whether the Mustang or Camaro is better, but the common feature of such polemics is that they represent simple and interesting questions. The topic of tyres, however, and if you dare raise it, may stun your companions into silence. Tyres are not simple and interesting. They are complex and boring – at least on the outside.

A surprisingly compelling subject

Dinner table, or social media, conversation may centre on arguments over which football team deserves to win the league, or whether the Mustang or Camaro is better, but the common feature of such polemics is that they represent simple and interesting questions. The topic of tyres, however, and if you dare raise it, may stun your companions into silence. Tyres are not simple and interesting. They are complex and boring – at least on the outside. Delve a little deeper, and they become items of sophistication and almost wonder. Mysterious, near-anonymous products that power many parts of the modern economy and society. Omnipresent, but no ingredients label. Emissions Analytics thinks you should be interested in tyres, and you should talk about them at dinner tonight.

But if you can’t face that quite yet, you should first of all attend our newly launched conferences in Europe and US on tyre emissions and sustainability. Many excellent events already exist in this sector, but the common factor is that they look at tyres from the inside out: from the industry perspective in how to make better tyres. Environmental concerns are now forcing us to look from the outside in: how can we mitigate the effects of tyres from their manufacture and usage. Regulation is coming – and has already arrived in California.

The tyre industry is highly sophisticated yet somewhat secretive. Challenging problems are solved quietly without disclosing the nature of the solution. European tyres have achieved combinations of grip, noise and rolling resistance to meet the requirements and demands and of the market, while US tyres have remained simpler in formulation as durability has remained the over-riding preference. Unlike vehicle manufacturers, which exist in spotlight of regulation and consumer interest, tyre manufacturers just get on with it. Witness the invention of synthetic rubber in the Second World War, which has defined the industry ever since.

The big challenges today are often environmental. How to makes tyres with more sustainable materials – however they be defined? How to reduce microplastic and volatile organic emissions in use? This is not a problem created by heavy battery electric vehicles, but the near elimination of tailpipe pollutant emissions from modern vehicles has brought it into focus – many vehicles now emit 90% below emissions standards for nitrogen oxides, carbon monoxide, and particles. Although distance-specific tyre mass emissions may be in long-term, like-for-like decline, this is increasingly offset by more vehicles on the road, more miles driven, heavier vehicles and more torque. Our testing suggests 26% tyre wear emissions from pure battery vehicles compared to equivalent full hybrids.

To counter this trend, new tyre formulations are being quietly brought to market to handle this heavier and ever more demanding vehicles. The immediate concern that ‘eco’ tyres could deliver such performance at the price of being more environmentally toxic appears to not to be simplistically true from Emissions Analytics’ latest testing. On our toxicity potential metric, these eco tyres may in fact be a quarter or more less toxic than standard tyres. This could to a great extent neutralise the increased mass wear rates, but with two caveats, First, it requires detailed analytical testing to verify this. Second, these eco tyres come at a financial price to the consumer.

While the focus in such matters of regulation tend to start with new products, it may be regulations about replacement tyres that will have a greater bearing on the combined environmental of tyres. A brand-new battery vehicle equipped with the latest, most sophisticated eco tyres limit emissions, only for that good work to be undone when they are ultimately replaced by cheaper, less sophisticated alternatives. A private saving for the vehicle owner may create a public cost in pollution.

Seeking to address these questions, our next event will take place in Prague on 11-12 February 2025, and further details can be found here. Two months later, on 30 April - 1 May 2025, we will pick up the discussion in Southern California, details here. We encourage you all to apply to attend and submit abstracts for presentations.

Alongside this, we will be publishing regular, detailed results of Emissions Analytics’ tyre wear and chemical composition testing, along with our monthly newsletter, via our Emissions Intelligence subscription – please contact us to find out more.

Together, these new initiatives from Emissions Analytics are engaging with society and industry to bring about an understanding and appreciation of the sheer cleverness and importance of tyres, and how vital the right choices are for the environment. Consumers want to do the right thing, but the choice of tyres for many is currently too boring and complex. Let’s change this. Let's start the conversation.

Presentation: Emissions Analytics Tire Technology Expo Presentation 20 March 2024

Our CEO & Founder, Nick Molden recently spoke at the Automotive Tire Technology 2024.

Webinar: Tyre emissions from the latest electric vehicles

Our CEO & Founder, Nick Molden presented a webinar on the tyre emissions from the latest electric vehicles on 19th September 2023. The world is on a path to electrifying everything that moves, primarily driven by the desire to decarbonise. But no vehicle is zero emission, and the latest emissions regulations in Europe, the US and beyond are now starting to incorporate non-exhaust emissions.

Our CEO & Founder, Nick Molden presented a webinar on the tyre emissions from the latest electric vehicles on 19th September 2023.

To watch the webinar and download the presentation please see below.

The world is on a path to electrifying everything that moves, primarily driven by the desire to decarbonise. But no vehicle is zero emission, and the latest emissions regulations in Europe, the US and beyond are now starting to incorporate non-exhaust emissions. The task is a major one, though, as changes in other regulations and tastes are leading to ever-heavier vehicles, which is likely to increase tyre emissions. What is less well understood is the chemical formulations used in specialist 'EV tyres', and whether they are potentially more or less toxic that standard tyres. This webinar will share the latest chemical profiling results from our EQUA test programme, to show the key trends.

This is particularly relevant in the light of the California Environmental Protection Agency’s new rule on chemical composition, aiming to reduce the use of the toxic 6PPD preservative. We will show the extent to which alternatives are already being used. We will also consider the progress the European Union is making on its Euro 7 regulation for tyres. Current proposals for a measurement method fromt he Task Force on Tyre Abrasion will be reviewed in the light of our real-world wear rate testing. How efficient and effective will the proposed method be, and what might an optimal initial limit value look like? This testing fits within Emissions Analytics’ expanded EQUA test programme, which includes regulated and unregulated tailpipe emissions and vehicle interior air quality. Watch out for future webinars on these topic, and do subscribe to Emissions Analytics' newsletter to find out about priority access.

Emissions Analytics and the University of Portsmouth collaborate on the study to investigate impact of toxic tyre chemicals in UK waters

Emissions Analytics is thrilled to be featured in a groundbreaking news article by the University of Portsmouth. The article, titled "Study to Investigate Impact of Toxic Tyre Chemicals in UK Waters," sheds light on a crucial research endeavor that aims to understand the environmental consequences of tyre chemical pollutants.

Emissions Analytics is thrilled to be featured in a groundbreaking news article by the University of Portsmouth. The article, titled "Study to Investigate Impact of Toxic Tyre Chemicals in UK Waters," sheds light on a crucial research endeavor that aims to understand the environmental consequences of tyre chemical pollutants.

To learn more about this groundbreaking study and the role of Emissions Analytics, we invite you to read the full article on the University of Portsmouth's website. Click here to access the article and delve into the research that is shaping the future of environmental sustainability.

Following the tyre tracks… Where do tyre emissions go?

We know, from earlier research, that tyres emit lots of particles, both coarser and the more potentially dangerous ultrafines. To put this in context, the levels are less than from exhausts of many older diesel vehicles without filters, but orders of magnitude greater than from the exhausts of modern internal combustion engine vehicles with the latest filters. But, where do these particles go, and can they be found in the environment?

We know, from earlier research, that tyres emit lots of particles, both coarser and the more potentially dangerous ultrafines. To put this in context, the levels are less than from exhausts of many older diesel vehicles without filters, but orders of magnitude greater than from the exhausts of modern internal combustion engine vehicles with the latest filters. But, where do these particles go, and can they be found in the environment?

As a consequence of the size distribution of particles in tyre wear, as set out in our earlier newsletter, it is reasonable to believe that the particles go to air, soil and water. Some particles will be directly deposited on the road verge or in rivers near roads, but the smaller ones will settle further away after a period of time. The tyre particles contain on average over 400 organic compounds, plus a range of metals. Together, this makes for a complex product that is emitted into the environment in many different ways.

Compare this with tailpipe emissions. While there are many volatile organic compounds in exhaust fumes, the pollution is dominated by carbon dioxide (CO2) and nitrogen oxides in modern vehicles, with some carbon monoxide and ultrafine particles. Therefore, the environmental impact is dominated by a small number of compounds almost all of which are suspended in air for an extended period.

The differences between tyre and tailpipe emissions presents an interesting paradox: as tyres are more complex, they may leave a more easily identifiable fingerprint in the environment. If we take an air sample and observe some CO2, it is impossible to ascribe that to a source, whether vehicular or from human exhalation. Even with NOx, it is impossible to say whether that comes from a car, truck, home heating or an industrial source. In contrast, if we find some benzene‚ 1‚2‚4-trimethyl- in river water, for example, there is a fair chance it originated from tyres. Seeing multiple compounds in the environment that we know can come from tyres only increases that confidence. The very complex nature of tyres means such a fingerprint can be left. In contrast, for tailpipe emissions, we have to fall back on constructing ‘inventories’ – look-up tables containing average values – to characterise what emissions come from different types of vehicle, derived from testing those vehicles, and often combined with activity data.

Although it took many years of work, researchers in the US were eventually able to link the death of significant numbers of coho salmon, and latterly also trout, to the chemical preservative 6PPD in tyres. This was covered in our earlier newsletter, 'Fishy'. Therefore, it is complex, but possible, to determine the original source of pollutants or causes deleterious effects observed in the environment. How can this approach be generalised?

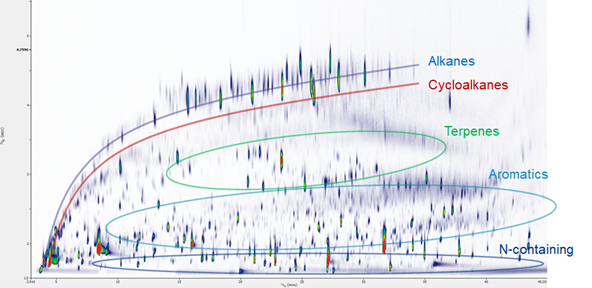

Emissions Analytics has compiled a database of organic compound profiles of hundreds of different tyre models, drawn from over 40 different brands. To achieve this, we have developed a highly optimised analytical pyrolysis method to understand as closely as possible the compounds in the original tyre. This method uses a two-dimensional chromatography system to separate the compounds, which are then identified and quantified using a time-of-flight mass spectrometer. From this, the chemical fingerprint of an ‘average’ tyre can be determined by taking the mean concentration of each compound across all the tyres analysed.

Taking a real sample, we can see how this fingerprinting might work. A water sample was taken from an undisclosed body of water that was believed potentially to contain contaminants or leachates from tyres. It was analysed by ‘solid-phase microextraction’, which essentially involves dipping a thin fibre into the water, which extracts the compounds within. A blank sample of water should show no organic compounds on the chromatogram. Analysis of the sample in fact identified 115 organic compounds, many at the parts-per-billion level. The chromatogram is below, which shows compounds across a wide area and, consequently, many different functional groups.

From this we can conclude that there is very likely to be contamination in this water sample. However, how confident can we be that it comes from tyres?

To assess this, we can aggregate the individual compounds represented by the peaks on the chromatogram into functional groups based on their chemical properties: acids, alcohols, aldehydes, and so on. From an environmental and health perspective, the aromatics group is the most concerning as they are often carcinogenic. The esters and terpenes functional groups represent the least concerning compounds, and are most commonly fragrances and flavours. To estimate the prevalence of each group, the area under the peak on each compound is taken, and expressed as a percentage of the total peak area across the whole chromatogram. This gives a chemical profile of the water sample. This can then be compared with the concentrations of chemicals in the Emissions Analytics’ database, averaged across all the tyres tested, in nanograms of target chemical per milligram of sample. The chart below then compares these measures of prevalence between the water sample and the reference database.

The most striking element is the peak of aromatics, which gives good evidence that it is chemicals from tyres that are present in the water. The biggest difference is in the terpenes, principally limonene, which are generally not water soluble and therefore float, so are likely to have been under-sampled. As well as the similar aromatic peaks, there are similar absences of acids and esters between the two samples. The presence of some compounds from the aldehyde and alkane groups suggests the presence of a low level of non-tyre pollution as well in this water sample. Overall, this is a simplified version of what is possible, as more granular functional groups, and even individual compounds, can be used in the fingerprinting.

The same essential approach can be applied to identify tyre wear compounds in soil. Previous research typically identified a small number of organic ‘tracer’ compounds and then used one-dimensional gas chromatography and mass spectrometry (GC-MS) to measure those tracers in the environmental sample. In a recent paper in Chemosphere, ‘Determination of tire wear markers in soil samples and their distribution in roadside soil’, styrene-butadiene rubber (SBR) was used as the tracer, together with thermal desorption and GC-MS, to quantify the distribution of tyre wear at different distances from the roadside. In a further paper in Critical Reviews in Environmental Science and Technology from 2022, ‘Tire wear particles: An emerging threat to soil health’, the use of traditional tracers such as 2-(4-morpholinyl) benzothiazole and hydrogenated resin acids was mentioned, but indicated the need for new and better markers that do not easily leach into water, and are resistant to heat and light exposure. The approach to fingerprinting water samples using two-dimensional gas chromatography and a fingerprinting database may provide that way forward.

Less has been done so far on looking for ultrafine tyre particles in air. Almost by definition, there will be low mass concentrations of tyre particles in air, due to their small size. This is likely to underestimate the potential health effects of such particles, due to their large relative surface area, and the potential for transporting other pollutants, such as VOCs, deep into the human body. This remains, however, work in progress without definitive conclusions. For now, Emissions Analytics is collecting particles as they are shed from tyres in real driving environments. Inevitably, such collection gathers some proportion of non-tyre particles, such as from brakes, road wear and resuspension. The same essential fingerprinting process is being used to estimate what that proportion of non-tyre ‘interference’ in a sample is.

In short, while tyres are highly complex products, containing hundreds of different chemical compounds, the latest analytical techniques present the opportunity for more sophisticated fingerprinting techniques compared to traditional tracer analysis. The tyre tracks can now be followed to understand the ultimate fate of tyre wear in the air, soil and water, and indirectly the effect on human and animal health.

According to chemistry, whisky is a solution

Whisky comes with much history, folklore and personal tastes, but it is also big business that thrives as a premium product made with high quality methods. Liquid sunshine is also complex chemistry.

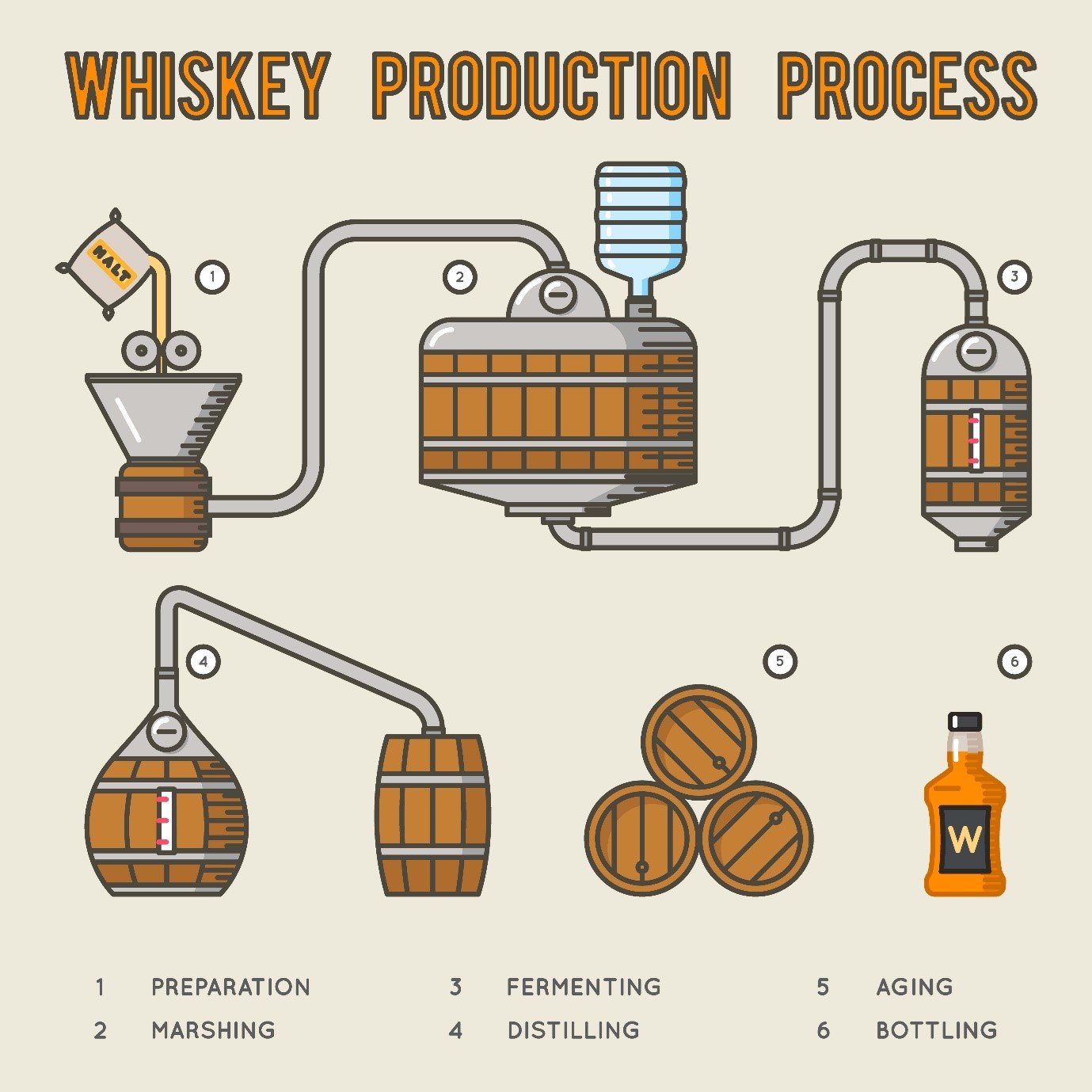

Whisky comes with much history, folklore and personal tastes, but it is also big business that thrives as a premium product made with high quality methods. Liquid sunshine is also complex chemistry. The manufacturing process is deep science with a dash of art, which requires high skill to create perfectly balanced flavours and odours, but also sets up the incentive and possibility for fraud and adulteration.

Oxford Indices’ background is in advanced data origination and analytics, primarily in the automotive, food and beverage markets. Across these diverse markets, the power of the latest methods in analytical chemistry can illuminate the mix of organic chemical compounds present, whether that is in a vehicle exhaust or manuka honey. The nature and size of the sector has enticed Oxford Indices to set about understanding the increasingly diverse and global range of whiskies.

A whisky is made up primarily of organic compounds – those containing some combination of carbon atoms and most often hydrogen atoms – of which there can easily be 50 or more in an individual product. These compounds define the flavour and strength of the whisky but can also bring undesirable health effects or other characteristics. The most common classes of compounds include lactones, phenolics, aldehydes and esters, which arise from the various stages of the production process shown below.

As each whisky has its own unique combination of compounds, we tested 50 different products, covering 36 different single malts and 14 blends, drawn from around the world. Each was sampled from recently opened bottles stored in controlled conditions, and then analysed in our laboratory using liquid injection into a two-dimensional gas chromatography and time-of-flight mass spectrometry system from Markes International and SepSolve Analytical.

The benefit of this analytical approach is that the two dimensions of the chromatography allow for near-complete separation of all the organic compounds, in a way not possible with standard one-dimensional separation, which is limited by coeluting peaks on the chromatogram. The time-of-flight mass spectrometry allows for powerful identification of the separated compounds even using standard spectral libraries. With a sensitivity down to parts-per-billion, trace amounts of compounds can be discovered effectively by this approach.

Taking a specific example, of the Kavalan single malt whisky from Taiwan, we can see below that, grouping the compounds for generic functional groups, unsurprisingly the overwhelmingly most abundant compounds are alcohols. The measure of ‘peak area %’ refers to the area under the peaks on a chromatogram, as a fraction of the sum of the areas under all the peaks. While not exactly a measure of concentration, it is a good measure of relative abundance.

The alcohol group is dominated by ethanol, with 1-butanol‚ 3-methyl- in fact being more prevalent, along with lower concentration compounds such as 1‚3-butanediol and 1-octanol. While some flavourings arise from these alcohols, the greater complexity comes from the long tail of low concentrations compounds in the other groups, including lactones, phenols, aldehydes and furans, that can be picked up by the sensitive human palate.

Drilling into more detail with Kavalan, the table below takes the ten flavour compounds with the lowest abundance in the sample. The average peak area of these is just 0.019% of the total, which demonstrates the ability of this technique to see very low concentrations. Moreover, when testing multiple samples, a high degree of repeatability is achieved. Despite the low concentrations, it is possible to see the complexity and nuance that are created by the fermentation, distillation and ageing processes.

At the same time, it is also possible to identify less desirable compounds in the final whisky product. This can be used to pinpoint contamination or adulteration, but also chemicals that are intermediate compounds that do not contribute to the ultimate flavour and may even be undesirable. Across all the whiskies tested, compounds in this category include pentaethylene glycol, acetic acid, nitro-, methyl ester and α-toluenethiol – all of which can be irritants to the skin, eyes and lungs if present at relatively high concentrations.

A corollary of being able to identify this range of compounds is that we can then compare and contrast different products. Principal Component Analysis (PCA) is used to reduce the complexity of making comparisons. With dozens of compounds in whiskies, the comparative analysis would be impossible to understand. The PCA use a best-fit approach to create axes that a synthesis of multiple compounds, as shown below.

Each colour identifies a different whisky, each of which was sampled multiple times. As a broad overview, there are two main clumps of whisky brands (labelled as Groups 1 and 2 above) and then a small number of outliers. The first principal component (PC1) most notably accounts for the difference between the two main groups, and this dimension comprises compounds including furfural (woody, bready, nutty), hexanoic acid‚ ethyl ester (sweet, pineapple, fruity flavour) and acetic acid (pungent, sour, overripe fruit). Furthermore, within Group 1, PC1 is the main differentiating factor. This group includes six single malts – mostly Highland and Speyside – and one blend.

In contrast, within Group 2, the main differentiating dimension is PC3, which combines compounds such as propanoic acid‚ 2-hydroxy-‚ ethyl ester (fruity, creamy, pineapple-like), phenylethyl alcohol (floral, rose, bready) and 1-butanol‚ 3-methyl- (fruity, banana, ethereal). This group includes 18 single malts and five blends. The most notable outlier of all is the whisky that is differentiated in the PC2 dimension (at the top of chart, marked in brown), which is defined by a single compound: d-methionine (an amino acid). This product is Ledaig 10 Year Old, an Island whisky from Tobermory in Scotland. This amino acid is sometimes described as having an old potato smell, and reviews of the whisky mention seaside and waxy aromas.

Kavalan, from Taiwan, also stands out in the PCA plot as an outlier, at the extreme left of the PC1 dimension. Other distinct products are the Jura 10 Year Old and Ardbeg 10 Year Old, Island and Islay single malts respectively. The final outlier is a blend: Nomad Outland. This is notable as a blend of malts from Scotland, but matured between both Scotland and Spain.

Focusing further on blended whisky, using this sample method, it is possible to identify similarities between these and single malts. This can be useful in assessing how successful producers are at mimicking the characteristics of more expensive single malts through blending. The one blend in Group 1 is from Australia, and is clustered with Speyburn and Highland Park products.

Within Group 2, two of the blends are from different distilleries in Japan, but which share much commonality. Furthermore, these Japanese blends are also similar to blends from Great Britain and a Scottish/US mix – and all of which share similarities with a Lagavulin product from Scotland. Perhaps there is a tendency towards similarity between blends as the different single malt components – put loosely – average themselves out. The chart above shows how the blends (in blue) cluster relative to the single malts (in red).

The next stage in this project is to expand the dataset further, to hundreds of whiskies, to reveal patterns and correlations reflecting geographies, maturation process, ageing and other factors. In early 2022, Oxford Indices will launch a research database that will show the individual compounds detected and their relative concentrations. Characterising the market of whiskies to this level detail presents many opportunities, from engineering new products to protecting the value in an important and high-value sector.

What's in a tyre?

Thousands of chemicals derived from crude oil, many of them volatile organic compounds, apparently. This matters because tyres shed a lot of material into the environment.

Thousands of chemicals derived from crude oil, many of them volatile organic compounds, apparently.

This matters because tyres shed a lot of material into the environment. Emissions Analytics’ estimates suggest that around 300,000 tonnes of ‘rubber’ are released every year from passenger cars in Europe and US alone, the equivalent of over forty million brand new, entire tyres. These particles go into the air, soil and watercourses. If you were to stack all the tyres manufactured in the world in a year on their side, it would reach the moon.

While there is a tyre labelling scheme in the EU, it only rates rolling resistance, wet grip and noise. These are clearly vital to the performance and safety of tyres, but it leaves the ratings blind to the environmental consequences of the tyre wear emissions. There are restrictions on toxic chemicals that can be included in the manufacture of tyres under the European REACH regulations, but the number of chemicals affected is limited.

While we have been occupied with reducing exhaust emissions to control air quality problems, other sources of pollutants have not received the same attention historically. Now that tailpipe emissions of modern internal combustion engines (ICEs) in both Europe and US are generally well below regulated limits for pollutants, focus is now turning to ‘non-exhaust emissions’, which cover tyres. Emissions Analytics’ testing shows that, in normal driving, tyre wear emissions are about one hundred times greater than tailpipe particle mass on a modern ICE vehicle. In legal but extreme driving, enough to reduce significantly the lifespan of a vehicle’s tyres, that factor increases to around one thousand.

In addition to tyres, non-exhaust emissions cover material from brake and road wear, as well as resuspended solids, whipped up from the carriageway by the moving vehicle. Of these, tyre wear emissions are probably the largest and fastest-growing component. Brake wear emissions are forecast to fall as regenerative braking becomes more widespread. Road wear and resuspension rates are only partly related to the passing vehicle, including its weight, but are probably more determined by the road material and condition, and what particles are blown onto the road from multiple surrounding sources. Tyre wear emissions are likely to grow as vehicles continue the long-term trend of becoming heavier, although this may at some point be offset by using more lightweight construction materials.

Understanding tyre wear emissions provides a challenge as they are heterogenous. Unlike, for example, nitrogen oxide (NOx), which is a unique compound that can be measured as a mass or volume, particles from tyres come in an infinite combination of shapes, sizes and densities. Moreover, the particles are made up of a wide array of chemical compounds, and these chemicals may also stick – or adsorb – to the surface of the particle. In this way, particles can act as the distribution vector for other compounds.

An emerging approach to characterising tyre wear emissions is, therefore, to measure both the wear rates and chemical make-up of the particles. This enables a quantification of the amount of individual chemicals that are released into the environment. This information can then be put together with toxicity ratings to assess the potential effect on human health, wildlife and biodiversity. For the semi-volatile organic compounds particularly, the effect of these on secondary organic aerosol formation – in other words, gaseous emissions that condense to become airborne particles over time – can be evaluated.

To begin to understand the degree and nature of the tyre wear emissions problem, Emissions Analytics recently tested a range of different tyres. Full sets of tyres of eight different brands and types were selected and installed on the same test vehicle, a 2012 rear-wheel drive Mercedes C-Class. The wheel alignment and tyre pressures were checked. Each set of tyres was driven for over 1,000 miles, around 90% by distance being conducted on the motorway. The four wheels – i.e. leaving the tyres on the rims to avoid damage – were weighed at the start and end, and the distance-specific loss of mass was calculated. The results are shown in the chart below.

Across the brands, the average mass loss was 64mg/km for the vehicle, adding all four tyres together. Wear on the rear tyres was greater, accounting for 71% of the total on average, strongly influenced by this being a rear-wheel drive car. The wear rate on the fastest abrading tyre was 2.3 times higher than the slowest. Therefore, tyre choice by manufacturers and consumers can have a material impact on emissions rates.

The wear rate is faster when tyres are new, for the first few thousand miles. Thereafter, the wear rate appears to decline at an approximately logarithmic rate. Over a lifetime, therefore, the average wear rate may be half the figures above. If we assume that the average vehicle travels around 16,000km per year, the rates above mean that each car sheds around 0.5kg per year on average over its lifetime. As there are almost 600 million vehicles in Europe and the US, this is equivalent to 300,000 tonnes of particles. An average tyre weights around 8kg, hence the total amount shed is equivalent to almost 40 million whole tyres. These figures do not include tyre wear from heavy-duty vehicles, which would also be significant.

The effect of particles on human health and the wider environment is an on-going and active area of research. It is complex to isolate the causal links. In terms of air pollution, it is generally accepted that there is a connection between particle mass emissions and diseases such as cancer and heart disease from prolonged exposure. The effects in terms of particle number are less clear-cut, although the EU regulates these at the tailpipe from a precautionary motive. The aim of this newsletter is not to review the evidence, but rather to contribute early findings on the chemical composition of tyres studied so far by Emissions Analytics.

Tyres are highly-engineered products and made up of a complex mixture of substances. For light-duty vehicles, the majority of the content of the tyre tread and walls comes from crude oil derivatives, with only a minority of natural rubber. Therefore, to understand the composition of tyres, it is necessary to employ a technique that can separate these out. We decided to focus on the organic compounds rather than metals, and employed our two-dimensional gas chromatography equipment coupled with a time-of-flight mass spectrometer (GCxGC-TOF-MS from SepSolve Analytical and Markes International, see https://www.emissionsanalytics.com/tyre-emissions). The gas chromatograph achieves separation by passing a sample through a long ‘column’, and the mass spectrometer does the compound identification. Two dimensions, both of time, are required to separate compounds that ‘elute’ in the same place in a one-dimensional chromatogram. Taking an example tyre, we heated samples to 100˚C and analysed the compounds released to obtain the following two-dimensional chromatogram.

Broadly, compounds cluster in different areas depending on common chemical characteristics. Some frequently used groups are illustrated above. Alkanes (e.g. pentane) typically affect the lungs, liver, kidney and brain. Cycloalkanes (e.g. cyclohexane) lead to headaches and dizziness. Terpenes (e.g. limonene) are generally less problematic and are responsible for aromas, unlike aromatics (e.g. benzo(a)pyrene), which are often carcinogens, as are nitrogen-containing compounds (e.g. quinoline). This is a significant simplification for the purposes of illustration.

Each shaded area on the chromatogram indicates a distinct chemical, with the intensity of the colour reflecting its abundance. The measurement breadth of the equipment is from compounds containing two carbon atoms (C2) to at least C44. This covers what are called volatile organic compounds (VOCs) and semi-volatile organic compounds (SVOCs). Just this one sample contains well over a thousand distinct compounds of these types.

The next stage is to identify as many of the compounds as possible and understand if they are problematic for health or the environment. Zooming in on the nitrogen-containing part of the chromatogram, it is possible to identify a number of potentially problematic compounds, as shown below.

N-Phenyl pyrrole, quinazoline, 4-tert-butyl-2-chlorophenol at certain levels of exposure can lead to symptoms in humans including skin, eye and respiratory irritation. In addition to these effects, quinoline and 3-methyl-quinoline have potential carcinogenicity and mutagenicity in humans. Quinoline and 1,2-dihydro-2,2,4-trimethyl affect aquatic environments more than humans.

This suggests that potentially concerning compounds are present in tyres, but if we compare the composition of different tyre brands it is also possible to see that the mix of chemicals differs. This reflects the many formulations used by different producers, but also means that tyre selection can lead to different environmental and health effects. The chart below illustrates the point by comparing four different tyre types. Each sample was pyrolysed to release as many compounds in the underlying materials as possible, and then analysed using Principal Component Analysis.

Tyre Brand B is strongly differentiated from the other three tyres by the presence of 1-methyl-2-pentyl-cyclohexane – a cycloalkane. Although it does not have any particular toxic indications for humans, it is potentially possible to relate the presence of this defining compound to other characteristics such as rolling resistance, noise or wet grip.

Where toxic compounds are identified by this approach, it does not guarantee that they are present in amounts that could cause harm. Therefore, the final stage is to quantify each in the sample, so the total amount in a tyre can be worked out. However, even if the amounts are small in one tyre, due to the large amount of material released each year in total – as calculated above – even low concentrations could lead to deleterious effects at the macro level.

All in all, this initial testing has demonstrated that it is possible to measure tyre wear explicitly, without it being combined with brake or road wear, and the separation capability of the two-dimensional gas chromatograph can help identify thousands of constituent compounds. The results themselves then show that there are relevant and material differences in the wear rates and chemical make-up of different brands and models of tyre. Therefore, choices of tyre when the car is first sold and at subsequent tyre changes are directly relevant to the vehicle’s environmental impact, and requires deeper and urgent study.